| Title and Reference |

Abstract |

HAL/S Documentation-

HAL/S Compiler System Specification

-

HAL/S Language Specification

-

HAL/S Programmer's Guide

-

HAL/S-FC User's Manual

-

Programming in HAL/S

|

|

|

Shuttle ALT Free Flight 1: GPC 2 Failure

|

Introduction

The separation event was marked by a sharp, but not loud,

explosive sound and a brief, sharp, upward lurch. Neither the noise nor

the jolt were particularly distracting and did not affect the

accomplishment of the planned procedures. Immediately after the

separation event, a master alarm occurred and a computer caution and

warning light, a computer annunciation matrix column on general purpose

computer 2, and a big "X" on cathode ray tube 2 were noticed . |

|

Shuttle ALT Flight 1A: GPC 3 Failure

|

Summary

General purpose computer 3 failed during preflight checks for captive-active

flight 1A on June 17, 1977, at 14:33:04. The central processing unit and

input-output processor both stopped executing. No built-in test equipment

error indications were generated. Troubleshooting, including

thermal cycling, has not caused the problem to recur. The problem cannot be

further isolated by analysis, so the actual cause cannot be determined.

|

|

Space Shuttle Technical Conference

Lyndon B. Johnson Space Center

June 28-30, 1983

NASA Conference Publication 2342

General Chairman: Aaron Cohen |

Abstract

This publication is a compilation of the papers prepared for the Space

Shuttle Technical Conference held at the NASA Lyndon B. Johnson Space

Center, Houston, Texas, June 28-30, 1983. The purpose of this conference was

to provide an archival publication for the retrospective presentation and

documentation of the key scientific and engineering achievements of the

Space Shuttle Program following the attainment of full operational status by

the National Space Transportation System.

To provide technical disciplinary focus, the conference was organized

around 10 technical topic areas: (i) Integrated Avionics, (2) Guidance,

Navigation, and Control, (3) Aerodynamics, (4) Structures, (5) Life Support,

Environmental Control, and Crew Station, (6) Ground Operations, (7)

Propulsion and Power, (8) Communications and Tracking, (9) Mechanisms and

Mechanical Systems, and (10) Thermal and Contamination Environments and

Protection Systems.

The papers in each technical topic which were presented over the 3-day

conference period provide a historical overview of the key technical

problems and challenges which were met and overcome during the development

phase of the Space Shuttle Program. Taken as a whole, these papers provide a

valuable archival reference to the magnitude and scope of this major

national achievement.

|

|

Inadvertent Firing of L1L, L1U, R4U, F3L, and F3U (ORB)

|

Power-on Reset Problem

Primary reaction control system (RCS) thrusters L1L, L1U, R4U, F3L, and F3U

inadvertently fired simultaneous 80-msec pulses at 035:11:41:06 G.m.t.

(001:06:19:02 MET) when aft flight controller power was switched on. The

firing was consistent with a +Y/+Z translation command response. The crew

reported that the aft station translational hand controller (THC) had not

been deflected. |

|

Single Event Upsets for Space Shuttle Flights of New General Purpose

Computer Memory Devices

P.M. O'Neill and G.D.Badhwar

NASA

IEEE Trans. on Nuclear Science, Vol. 41., No. 5

October 1994

pp. 1755 - 1764

|

Abstract

The replacement of magnetic core with a well characterized

semiconductor memory in the Space Shuttle orbiter general purpose computers

(GPC's) has provided a wealth of on-orbit radiation effects data since 1991.

The fault tolerant GPC's detect, correct, and downlink memory upset status

and orbiter position information every few seconds, giving us the ability to

correlate 1400 upsets to date with altitude, geomagnetic latitude, and solar

conditions. The predicted upset rate was computed by a modified path-length

distribution method. The modification accounts for the Weibull distribution

cross-section (rather than a single upset threshold) and the device

sensitive volume thickness. Device thickness was estimated by the method

normally used to account for edge effects at the upset cross-section

discontinuity that occurs at ion changes. A galactic cosmic ray environment

model accurately models the average particle flux for each mission. The

predicted and observed upset rates were found to be in good agreement for

sensitive volume thicknesses consistent with the device's fabrication

technology. |

|

The "Bug" Heard 'Round the World

Jack Garman

NASA, Johnson Space Center

ACM Software Engineering Notes

October, 1981, pp. 3-10. |

Introduction (excerpts)

Discussion of the software problem which delayed the first Shuttle

orbital flight.On April 10, 1981, about 20 minutes prior to the scheduled

launching of the first flight of America's Space Transportation System,

astronauts and technicians attempted to initialize the software system which

"backs-up" the quad-redundant primary software system ......and could not.

In fact, there was no possible way, it turns out, that the BFS (Backup

Flight Control System) in the fifth onboard computer could have been

initialized properly with the PASS (Primary Avionics Software System)

already executing in the other four computers. |

|

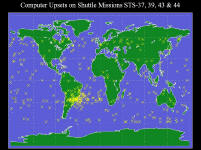

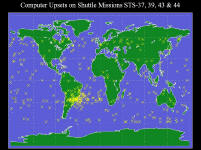

Computer Upsets on Shuttle Missions STS-37, 39, 43, and 44

From

http://www.ngdc.noaa.gov/stp/GOES/sts.pdf |

|

|

Distributed Processing on the Space Shuttle:

A Case Study

P. 5. Schoonmaker

McDonnell Douglas Technical Services Co., Inc.

Houston, Texas

AIAA Paper 81-2140 |

Abstract

This paper describes a study of centralized vs. distributed

processing approaches to the design and integration of a new Space Shuttle

Orbiter subsystem -- the Power Extension Package (PEP), a 25-kw solar array.

The objective of this study was to determine the "best" a l location of PEP

monitoring and control functions between the existing Orbiter Systems

Management (SM) computer and an autonomous PEP processor. Four candidate

functional configurations were defined, and a subjective, life-cycle

assessment of the re1ative merits o f these candidates was performed by the

study team. We concluded that the optimum configuration will (a) include

substantial processing "intelligence" in the PEP processor, and (b) make use

of SM computer "standard services". |

|

A GPS Receiver Upgrade For The Space

Shuttle – Rationale And Considerations

John L. Goodman

United Space Alliance LLC

40th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Fort

Lauderdale, FL, July 11-14, 2004.

AIAA-2004-3911 |

Abstract

In the mid 1990s, a 5 channel Global Positioning System (GPS) receiver was

integrated into the Space Shuttle avionics system due to the anticipated

start of Tactical Air Control and Navigation (TACAN) phase-out in the year

2000. While the early 1990s technology level receiver adds redundancy and

flexibility to the navigation process, and improves safety at emergency

landing sites, new capabilities in modern GPS receivers would further

enhance Shuttle navigation. All-in-view satellite tracking, new GPS signals

and ground and space based augmentation systems would provide a more robust

GPS navigation solution for the orbiters, particularly if future missions

call for automated landings, or on-board precision orbit determination. |

Lessons Learned From Flights of “Off the Shelf” Aviation Navigation Units on

the Space Shuttle

John L. Goodman

NASA Johnson Space Center, United Space Alliance, LLC

shuttle_gps_lessons_learned_may_02.pdf |

Abstract

The Space Shuttle program began flying atmospheric flight navigation units in

1993, in support of Shuttle avionics upgrades. In the early 1990s, it was anticipated that

proven in-production navigation units would greatly reduce integration, certification and

maintenance costs. However, technical issues arising from ground and flight tests

resulted in a slip in the Shuttle GPS certification date. A number of lessons were

learned concerning the adaptation of atmospheric flight navigation units for use in

low-Earth orbit. They are applicable to any use of a navigation unit in an application

significantly different from the one for which it was originally designed. Flight

experience has shown that atmospheric flight navigation units are not adequate to support

anticipated space applications of GPS, such as autonomous operation, rendezvous, formation

flying and replacement of ground tracking systems. |

The Space Shuttle and GPS – A Safety-Critical Navigation Upgrade

John L. Goodman

NASA Johnson Space Center, United Space Alliance, LLC

shuttle_gps_n_cots.pdf |

Abstract

In 1993, the Space Shuttle Program selected an off-the-shelf Global Positioning

System (GPS) receiver to eventually replace the three Tactical Air Navigation units on

each space shuttle orbiter. A proven, large production base GPS receiver was believed to

be the key to reducing integration, certification, and maintenance costs. More GPS

software changes, shuttle flight software changes, and flight and ground testing were

required than anticipated. This resulted in a 3-year slip in the shuttle GPS certification

date. A close relationship with the GPS vendor, open communication among team members,

Independent Verification and Validation of source code, and GPS receiver design insight

were keys to successful certification of GPS for operational use by the space shuttle. |

A Software Perspective on GNSS Receiver Integration and Operation

John L. Goodman

NASA Johnson Space Center, United Space Alliance, LLC

sw_perspective_on_gnss_rcvr_int_op.pdf |

Abstract

The GNSS industry is focusing on potential threats to satellite navigation

integrity, such as intentional and unintentional interference, signal-in-space (satellite)

and ground support infrastructure anomalies, shared spectrum issues, and multipath. The

experience of the International Space Station (ISS) program, the Space Shuttle program,

the Crew Return Vehicle (CRV) program and other users of GNSS indicate that navigation

outages due to receiver software issues may pose as great a risk, if not more, to the user

than threats currently under study. The improvement in GNSS receiver tracking

capability and navigation accuracy has been accompanied by an increase in software

quantity and complexity. Current and future GNSS receivers will interface with multiple

systems that will further increase software complexity. Rather than viewing GNSS receivers

as “plug and play” devices, they should be regarded as complex computers that

interface with other complex computers, sometimes in safety critical applications. The

high cost of meeting strict software quality standards, and the proprietary nature of GNSS

receiver software, makes it more difficult to ensure quality software for safety-critical

applications. Lack of integrator and user insight into GNSS software complicates the

integration and test process, leading to cost and schedule issues. |

Space Shuttle Avionics Upgrade. Issues and Opportunities

Richard A. Swain and Wiffiam B. Wingert

IBM, Systems Integration Division, Houston

Proceedings of the Twenty-Seventh Space Congress

Cocoa Beach, Florida, April 24-27, 1990

pp. 7-44 to 7-51 |

Abstract

The Space Shuttle uses a complex set of software and

hardware to guide, navigate and control it through all phases of flight. Five IBM AP-101B

flight computers host a set of highly critical and complex programs. The current

man-machine interface consists of a series of dedicated electromechanical instruments and

switches combined with specialized displays with limited function. The exponential growth

of microprocessor technology combined with the approaching obsolescence of the Space

Shuttle cockpit avionics have driven NASA to explore a Product Improvement Plan for the

Space Shuttle which includes the cockpit displays and controls.

The IBM Systems Integration Division (SID) in Houston is

currently studying alternatives for upgrading the Shuttle's cockpit. Some goals of the

upgrade include, Offloading of the main computers by distributing some of the avionics

display functions, reducing crew workload, reducing maintenance cost, and providing

display reconfigurability and context sensitivity. These goals are being met by using a

combination of off- the-shelf and newly-developed software and hardware. The software will

be developed using Ada, and must meet the timing constraints imposed by existing Shuttle

Systems. Advanced active matrix liquid crystal displays are being used to meet the tight

space, weight and power consumption requirements. These displays are tied to commercially

available 80386 microprocessors.

On top of the challenges presented by the software and hardware

development are programmatic constraints. These include: Transparency to existing Shuttle

avionics and data processing systems, Integration into training facilities:

avionics labs, simulators, aircraft, etc., Development of ground support systems: Software

Development facilities, verification capabilities, systems integration environments, etc.

and Installation into the operational Shuttle fleet without impacting current flight

rates. Of course, this all has to be done within cost and timing constraints in a dynamic

environment.

This upgrade holds promise for future improvements to the onboard avionics systems. An

example is online storage and display of crew checklists and procedures. This and other

potential growth paths must be accounted for in the design of this upgrade. The

opportunities for laying the groundwork of a cohesive strategy for avionics in the

nation's space fleet are many and the issues are complex but the technology has advanced

far enough that significant benefits can be achieved by upgrading the current system

making this a worthwhile if not mandatory task. |

Preventing Data Pollution in the Space Shuttle CockpitRobert

Hammett and Gary Schwartz, C.S. Draper Laboratory; William T. Smithgall , United Space

Alliance

IEEE/AIAA DASC, 2003

data_pollution_2003.pdf |

Introduction (excerpt)

Everyone is familiar with the problem of space junk, but the ongoing

battle with pollution inside the avionics of the space shuttle is little known. During the

original development of the space shuttle avionics system, designers of the fault tolerant

flight control system were concerned about the potential for faulty data being generated

by one computer being passed on to healthy computers, causing the recipients to fail. In

the extreme, this spread of “polluted” data can cause all redundant computer

systems to fail and can result in a serious safety hazard. Considerable effort was

expended to ensure this could not happen and the robustness of the shuttle avionics

has been proven by many flights. |

Shuttle Computer ComplexA.E. Cooper and W. T. Chow

Federal Systems Division

International Business Machines Corporation

Owego, N.Y.

Proceedings of the International Federation of Automatic Control,

Triennial World Congress, 6th, Boston and Cambridge, Mass., August 24-30, 1975.

shuttle_complex |

Abstract

The Shuttle Computer Complex provides the on-board data processing

capability for Space Shuttle Orbiter avionics. It performs the data processing necessary

for guidance, navigation, and control; payload handling and management; and performance

monitoring functions. It is made up of five interconnected but independent general purpose

computers to satisfy the overall avionics requirements in fault tolerance, partitioning,

and functional isolation. Each general purpose computer consists of a central processing

unit and an input/output processor; with the former performing all computations associated

with the application programs, and the latter controlling the transfer of information

between the computer and other subsystems of the Space Shuttle. The functions,

characteristics, mechanization, and operation of the Shuttle Computer Complex are

described in this paper. |

Software Reliability AnalysisP. N. Misra

IBM Systems Journal

Volume 22, Number 3, Page 262 (1983)

misra.pdfXL

misra.pdf |

Abstract

Methods proposed for software reliability prediction are reviewed. A case study is

then presented of the analysis of failure data from a Space Shuttle software project to

predict the number of failures likely during a mission, and the subsequent verification of

these predictions. |

Design-to-cost of the Spacelab avionics during Phase BAIAA PAPER

77-1493

Kayton, M.

TRW Defense and Space Systems Group

In: Digital Avionics Systems Conference, 2nd, Los Angeles, Calif.,

November 2-4, 1977, Collection of Technical Papers. (A78-12226 02-04) New York, American

Institute of Aeronautics and Astronautics, Inc., 1977, p. 89-95. |

Abstract:

Six alternative avionic designs considered during the Phase B (conceptual design

phase) of the European Spacelab development are described. Attention is directed to a

comparison of their hardware, software and integration costs, and to the impact of each

design on the Orbiter. Design 3 is chosen as the Spacelab baseline, where the subsystem

and experiment functions are separated into different computers and data buses so that the

experimenters' changes do not affect the unchanging system-support software.

General-purpose crew stations are provided for subsystems and experiments, but major

reliance is placed on dedicated panels. A data-bus system allows experimenters to connect

devices on pallets to the racks in the Spacelab without rewiring. An evolution of Design 3

avionics is believed to support Spacelab experiments for many years to come. |

| Independent Orbiter Assessment (IOA): Analysis of the

DPS subsystem NASA-CR-185549

Lowery, H. J., Haufler, W. A., and Pietz, K. C.

McDonnell-Douglas Astronautics Co.

Published: Oct 24, 1986

Pages: 123

Contract Number: NAS9-17650 |

Abstract:

The results of the Independent Orbiter Assessment (IOA) of the Failure Modes and

Effects Analysis/Critical Items List (FMEA/CIL) is presented. The IOA approach features a

top-down analysis of the hardware to independently determine failure modes, criticality,

and potential critical items. The independent analysis results corresponding to the

Orbiter Data Processing System (DPS) hardware are documented. The DPS hardware is required

for performing critical functions of data acquisition, data manipulation, data display,

and data transfer throughout the Orbiter. Specifically, the DPS hardware consists of the

following components: Multiplexer/Demultiplexer (MDM); General Purpose Computer (GPC);

Multifunction CRT Display System (MCDS); Data Buses and Data Bus Couplers (DBC); Data Bus

Isolation Amplifiers (DBIA); Mass Memory Unit (MMU); and Engine Interface Unit (EIU). The

IOA analysis process utilized available DPS hardware drawings and schematics for defining

hardware assemblies, components, and hardware items. Each level of hardware was evaluated

and analyzed for possible failure modes and effects. Criticality was assigned based upon

the severity of the effect for each failure mode. Due to the extensive redundancy built

into the DPS the number of critical items are few. Those identified resulted from

premature operation and erroneous output of the GPCs. |

Independent Orbiter Assessment (IOA): Analysis of the backup flight system Report Number: NASA-CR-185567

Prust, E. E., Mielke, R. W., and Hinsdale, L. W.

McDonnell-Douglas Astronautics Co.

Published: Dec 08, 1986

McDonnell-Douglas Astronautics Co. (Houston, TX, United States)

Contract Number: NAS9-17650 |

Abstract:

The results of the Independent Orbiter Assessment (IOA) of the Failure Modes and

Effects Analysis (FMEA) and Critical Items List (CIL) are presented. The IOA approach

features a top-down analysis of the hardware to determine failure modes, criticality, and

potential critical items. To preserve independence, this analysis was accomplished without

reliance upon the results contained within the NASA FMEA/CIL documentation. This report

documents the analysis results corresponding to the Orbiter Backup Flight System (BFS)

hardware. The BFS hardware consists of one General Purpose Computer (GPC) loaded with

backup flight software and the components used to engage/disengage that unique GPC.

Specifically, the BFS hardware includes the following: DDU (Display Driver Unit), BFC

(Backup Flight Controller), GPC (General Purpose Computer), switches (engage, disengage,

GPC, CRT), and circuit protectors (fuses, circuit breakers). The IOA analysis process

utilized available BFS hardware drawings and schematics for defining hardware assemblies,

components, and hardware items. Each level of hardware was evaluated and analyzed for

possible failure modes and effects. Criticality was assigned based upon the severity of

the effect for each failure mode. Of the failure modes analyzed, 19 could potentially

result in a loss of life and/or loss of vehicle. |

I/O error processing in the Space Shuttle onboard system AIAA PAPER

79-1952

Bassett, M. T. (IBM Corp.)

Published: Jan 01, 1979

Computers in Aerospace Conference, 2nd, Los Angeles, Calif., October

22-24, 1979, Technical Papers. (A79-54378 24-59) New York, American Institute of

Aeronautics and Astronautics, Inc., 1979, p. 416-422. |

Abstract:

The software design for dealing with I/O failures aboard the Space Shuttle Orbiter is

examined in four pieces - error detection, error isolation, error elimination and error

communication. The computer used is an IBM AP101 General Purpose Computer consisting of a

Central Processing Unit (CPU) and I/O Processor (IOP). The design of the IOP permits

software errors or failure/power-off of a device to disturb the acquisition of other data

in a chain of commands. One recovery method uses dynamic code modification to eliminate or

add segments to the chain. The design is made more interesting by the overall software

architecture which allows configuration of up to five AP101s as parallel processors

executing identical code sequences. Both the general software and hardware characteristics

are expanded upon in order to set the stage for the details of the error handling design. |

| Redundancy Management Technique for Space Shuttle

Computers Sklaroff, J. R. (IBM Corp.)

IBM Journal of Research and Development Volume: 20 Page: Jan. 1976

sklaroff.pdfXL

sklaroff.pdf |

Abstract:

This paper describes how a set of off-the-shelf general purpose digital computers

is being managed in a redundant avionic configuration while performing flight-critical

functions for the Space Shuttle. The description covers the architecture of the redundant

computer set, associated redundancy design requirements, and the technique used to detect

a failed computer and to identify this failure on-board to the crew. Significant

redundancy management requirements consist of imposing a total failure coverage on all

flight-critical functions, when more than two redundant computers are operating in flight,

and a maximum failure coverage for limited storage and processing time, when only two are

operating. The basic design technique consists of using dedicated redundancy management

hardware and software to allow each computer to judge the 'health' of the others by

comparing computer outputs and to 'vote' on the judgments. In formulating the design,

hardware simplicity, operational flexibility, and minimum computer resource utilization

were used as criteria. |

| Digital Processing Subsystem for the Space Shuttle Rubenstein, S. Z. Shroyer, L. O. (Rockwell International Corp.)

NAECON '74; Proceedings of the National Aerospace and Electronics

Conference, Dayton, Ohio, May 13-15, 1974. (A74-38517 19-09) New York, Institute of

Electrical and Electronics Engineers, Inc., 1974, p. 100-105. |

Abstract:

The main characteristics of the Digital Processing Subsystem and other major

subsystems and mission modes incorporated in the Space Shuttle are described. The DPS is

the primary control source for the other subsystems, and consists of a main computer

complex, serial data bus network, and a variety of control and data acquisition elements

interfacing with the data bus terminals. Among the functional elements described are: the

serial data bus network, general purpose computer, mass memory unit, multifunctional CRT

display system, multiplexer-demultiplexer, data acquisition and control buffer, engine

interface unit, mission events controller, display driver unit, and manipulator hand

controller. Selective explicit and implicit design constraints are progressively

introduced with an abridged design evolution to illustrate their importance. |

| Distributed processing on the Space Shuttle - A case

study AIAA PAPER 81-2140

Schoonmaker, P. B. (McDonnell Douglas Technical Services Co., Inc.)

Published: Jan 01, 1981

In: Computers in Aerospace Conference, 3rd, San Diego, CA, October 26-28,

1981, Collection of Technical Papers. (A82-10076 01-59) New York, AIAA, 1981, p. 165-172. |

Abstract:

A Power Extension Package (PEP) has been designed to provide additional electrical

power and energy during Shuttle sortie missions. The considered investigation was

conducted to determine the most suitable allocation of PEP monitoring and control

functions between the Orbiter's existing (centralized) Systems Management General Purpose

Computer and an embedded PEP processor. PEP monitoring and control functions are examined,

and a configuration definition is considered, taking into account the 'functional

migration' process, function allocation criteria, and candidate functional configurations.

A trade study is conducted, giving attention to an assessment of four candidate

configurations. Assessment factors are related to cost, development risk, aspects of

reliability and safety, PEP design complexity, PEP/STS integration complexity, flight

operations, and launch/landing site operations. A thorough (subjective) assessment of the

PEP system life cycle indicates substantial benefits from a distributed processing

approach. |

A Mass Memory Unit for the Space Shuttle OrbiterBrobst, R. E.

(Odetics, Inc.)

Published: Jan 01, 1976

In: International Telemetering Conference, Los Angeles, Calif., September

28-30, 1976, Proceedings. (A77-49851 24-32) Pittsburgh, Pa., Instrument Society of

America, 1976, p. 202-214. |

Abstract:

The paper describes a high-capacity, medium access time data system, the Mass

Memory Unit (MMU), developed to interface with the General Purpose Computers in the Space

Shuttle system. The MMU, which uses magnetic tape as the storage medium, will be used to

provide display format storage and will function as an auxiliary memory, used to store and

load/reload all phases of flight/ground software. The MMU is able to store 1.31 x 10 to

the 8th bits and has a nominal access time of 600 millisec. The data transfer rate is 10

to the 6th bits/sec and recording is at a packing density of 5000 bits/in. |

| Computers for the Space Shuttle Devore,

C.

Signal, vol. 32, Nov.-Dec. 1977, p. 41, 42, 44, 46. |

Abstract:

A general description of the onboard computer system for the Space Shuttle

Transportation System is given. The organization of the Centralized avionics is described,

and the data processing system hardware and bus terminal units are listed and their

capabilities are stated. A block diagram of the data processing system configuration for

the Orbiter 102 is shown. Five general-purpose computers interconnected with a variety of

interface units through a serial digital bus network comprise this system. |

The new AP101S General-Purpose Computer (GPC) for the Space Shuttle Norman,

P. Glenn (IBM Corp.)

IEEE, Proceedings Volume: 75 Page: 308-319

Mar 01, 1987

norman |

Abstract:

This paper describes the development of the new AP101S General-Purpose Computer

(GPC) for the Space Shuttle Orbiter. The AP101S evolved from a line of pipeline processors

flexible enough to support the Space Shuttle requirements. It offers many features vital

to the expected needs of the space program. This paper describes the design philosophy,

methodology, primary features, and functionality of the AP101S. The testing and

development, which led to the integration of the processor are also detailed. Finally, the

application of using it on-board the Space Shuttle Orbiter is portrayed. Indeed, the

AP101S is an integral part of an aggressive and expanding Space Shuttle program, and is

one which will serve well into the future. |

Space Shuttle Main Engine ControllerReport

Number: NASA-TP-1932 M-360

Mattox, R. M. and White, J. B.

NASA MSFC

Nov 01, 1981 |

Abstract:

A technical description of the space shuttle main engine controller, which provides

engine checkout prior to launch, engine control and monitoring during launch, and engine

safety and monitoring in orbit, is presented. Each of the major controller subassemblies,

the central processing unit, the computer interface electronics, the input electronics,

the output electronics, and the power supplies are described and discussed in detail along

with engine and orbiter interfaces and operational requirements. The controller represents

a unique application of digital concepts, techniques, and technology in monitoring,

managing, and controlling a high performance rocket engine propulsion system. The

operational requirements placed on the controller, the extremely harsh operating

environment to which it is exposed, and the reliability demanded, result in the most

complex and rugged digital system ever designed, fabricated, and flown. |

Advanced Engine Health Management Applications of the SSME Real-Time Vibration

Monitoring SystemTony R. Fiorucci1, David R. Lakin II1,

and Tracy D. Reynolds2

1 NASA MSFC

2 Optical Sciences Corporation

aiaa_2000_3622.pdf |

Abstract

This paper describes the operational capabilities of the Real-Time Vibration

Monitoring System (RTVMS) developed by the Marshall Space Flight Center (MSFC) for Space

Shuttle Main Engine (SSME) high-speed turbomachinery vibration diagnostics and failure

mitigation. RTVMS is now operational at the Stennis Space Center (SSC) during SSME static

test firings to provide real-time vibration analysis and health monitoring capabilities

during engine operation. The RTVMS produces real-time vibration spectral data from such

critical SSME components as the high pressure turbomachinery. From this data, discrete

spectral signatures, which are prime indicators of turbomachinery health, can be assessed

at high speeds and utilized to mitigate potential catastrophic engine failures. The

ability to monitor these potential failure indicators will allow the SSME Program to

develop a digital engine health monitoring system based on vibration analysis and, for the

first time in the history of the Space Shuttle flight program, activate a vibration flight

redline for the engine high pressure turbomachinery. |

Computers in Spaceflight: The NASA Experience

James E. Tomayko, Wichita State University

NASA Contractor Report CR-182505

1988, 417 pages.

|

Chapter Four: Computers in the

Space Shuttle Avionics System Notes: This book

examines the computer systems used in actual spaceflight or in close support of it. Each

chapter deals with either a specific program, such as Gemini or Apollo onboard computers,

or a closely related set of systems, such as launch processing or mission control. Also

published in Volume 18 of the "Encyclopedia of Computer Science and

Engineering", as published by Marcel Dekker, New York. All references can be found in

the Special Collections of Ablah Library, Wichita State University, Wichita, Kansas.

The links to the left points to the Chapter and sections on the Space

Shuttle's Computers. |

Achieving Reliability: The Evolution of Redundancy in American Manned Spacecraft

Computers

J.E. Tomayko

Wichita State University

Journal of the British Interplanetary Society

Vol. 38, pp. 545-552, 1985

tomayko_85.doc |

Abstract

Computers are a key component onboard manned spacecraft. Gemini,

Apollo, Skylab and the Space Shuttle all carried computer systems of increasing

functionality and complexity. All the computer hardware involved in those systems

was rated at 95 per cent reliability or better; yet in no case was a computer system

implemented without some alternative method of performing critical functions so that crew

safety was assured. How the National Aeronautics and Space Administration (NASA)

gained the last five per cent of near total reliability is the story of the evolution of

the concept of "backup" to the concept of "redundancy." Success

of this evolution is epitomized by the Shuttle, which did what no manned spacecraft had

ever done: carry men on its first test flight. The main factor in enabling

NASA to take such a risk was the redundancy built into the Orbiter. |

The Space Shuttle Primary Computer System

Communications of the ACM

September 1984 Volume 27 Number 9

pp. 872-900

shuttle_primary_computer_system.pdf |

Abstract

IBM's Federal Systems Division is responsible for supplying "error-free"

software for NASA's Space Shuttle Program. Case Studies Editors David Gifford and Alfred

Spector interview the people responsible for designing, building, and maintaining the

Shuttle's Primary Avionics and Software System.This copy is by permission of the

Association for Computing Machinery. The ACM permits copies of this article to be

made without fee provided that they are not made or distributed for direct commercial

advantage. |

Design, Development, Integration: Space Shuttle Primary Flight Software System

William A. Madden and Kyle Y. Rone

Communications of the ACM

September 1984 Volume 27 Number 9

pp. 914-925

madden_rone.pdf |

Abstract

The design, development, and integration of the Shuttle on-board Primary Avionics Software

System (PASS) have posed unique requirements associated with few other aerospace or

commercial software systems. These challenges stem from its size and complexity, its

criticality to completion of the Space Shuttle mission, and from the fact that it is only

one of many components of an overwhelmingly complex state-of-the-art Space Transportation

System (STS). This copy is by permission of the Association for Computing

Machinery. The ACM permits copies of this article to be made without fee provided

that they are not made or distributed for direct commercial advantage. |

Architecture of the Space Shuttle Primary Avionics Software System

Gene D. Carlow

Communications of the ACM

September 1984 Volume 27 Number 9

pp. 926-936

p926-carlow.pdf |

Abstract

PASS, perhaps the most complex flight computer program ever developed, epitomizes the

benefits to be gained by establishing a well-structured system architecture at the front

end of the development process. This copy is by permission of the Association for

Computing Machinery. The ACM permits copies of this article to be made without fee

provided that they are not made or distributed for direct commercial advantage. |

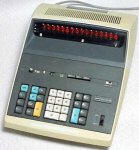

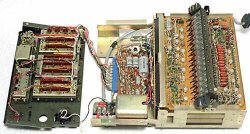

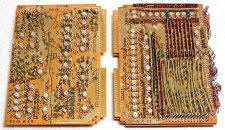

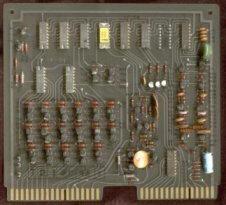

Space Shuttle On-Board

Computers |

Abstract

This small web page explains the Data Processing System aboard the NASA Space Shuttle (as

of the 1980s,early 1990s) along with unique images taken of my shuttle-flown CPU and IOP

units. |

Birds of a Feather?

How Politics and Culture Affected the Designs of the U.S. Space Shuttle and the Soviet

Buran

by Stephen J. Garber

January 2002

birdsfinalcomplete4.pdf |

Contents- Introduction: The Political and Cultural

Factors Argument; Background on the Two Shuttles; Literature Review

- How Technology and Politics Intertwined: The

U.S. Shuttle's Development; Energiya-Buran Development

- The Impact of Culture: U.S. Technological

Style and the Space Shuttle; Soviet Technological Style and the Energiya-Buran

- Summary and Conclusions

Appendices: - Key U.S. Figures

- Key Soviet Figures

- U.S. Bibliography

- Soviet Bibliography

- Chronology

- Glossary

- Curriculum Vitae

|

Space Shuttle Avionics System

Report No.: NASA-SP-504

January 1, 1989

SP-504 |

Abstract

The Space Shuttle avionics system, which was conceived in the early

1970's and became operational in the 1980's represents a significant

advancement of avionics system technology in the areas of systems and

redundancy management, digital data base technology, flight software, flight

control integration, digital fly-by-wire technology, crew display interface,

and operational concepts. The origins and the evolution of the system are

traced; the requirements, the constraints, and other factors which led to

the final configuration are outlined; and the functional operation of the

system is described. An overall system block diagram is included. |

Manned Spacecraft Automation and Robotics

Jon D. Erickson

Artificial Intelligence and Information Sciences Office

NASA Lyndon B. Johnson Space Center

Houston, TX 77058

Proceedings of the IEEE

Vol. 75, No. 3, March 1987, pp. 417-426

erickson_87 |

Abstract The Space Station holds promise of being a

showcase user and driver of advanced automation and robotics technology. The author

addresses the advances in automation and robotics from the Space Shuttle - with its

high-reliability redundancy management and fault-tolerance design and its remote

manipulator system - to the projected knowledge-based systems for monitoring, control;

fault diagnosis, planning, and scheduling, and the telerobotic systems of the future Space

Station. |